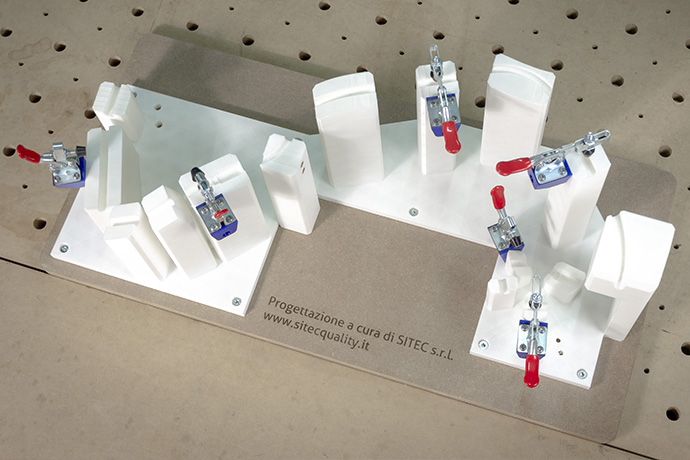

Jigs and Fixtures

Tooling and jigs help to improve the quality of the work of operators and technicians. Thanks to large format 3D printing it is possible to create tools to reduce human error and increase productivity at the same time.

The design is optimized based on the operator’s needs, and iterations can be performed swiftly and without constraints.

Boat Porthole

Even in the naval sector, 3D printing shows its incredible potential.

From interior customization, to tailor-made design for luxury boating, to functional elements.

The porthole was made of PLA HT, to withstand the subsequent resin coating process (60-70 °C) which will give the printed part greater resistance to salt.

Molds for bottles

Thanks to the large-format FFF technology, it is possible to produce dies for extrusion and blowing of large-sized thin-walled hollow products.

At the same time, 3D printing prototypes of bottles to test a new design several times, significantly reduces production time and costs.

PLA, PLA HT, PET, and Nylon are materials suitable for this type of application.

Orthopedic corset

The introduction of digital manufacturing accelerates and streamlines all labor procedures within an orthopedic laboratory, even in the production of custom-made corsets, thanks to large format 3D printers.

The design and production stages of an orthopedic corset are so simple, fast and accurate as to avoid all the more demanding phases, such as the manual acquisition of anthropometric measurements through plaster casts, up to saving time and materials in the final production phase.

Air Extractor

Born for competitions, the air extractor, or diffuser, is a fixed aerodynamic feature placed on the bottom of the car to increase the downforce values.

All this translates into an improved traction of tyres by allowing the car to move along a curve at higher speeds.

Thanks to our large format industrial 3D printer Fabbrix® ELEMENTO V2, it is possible to significantly speed up the long development time of this product, whether it is designed for competitions or for mass production, and directly carry out tests on circuits or in the wind tunnel for data acquisition and design validation.